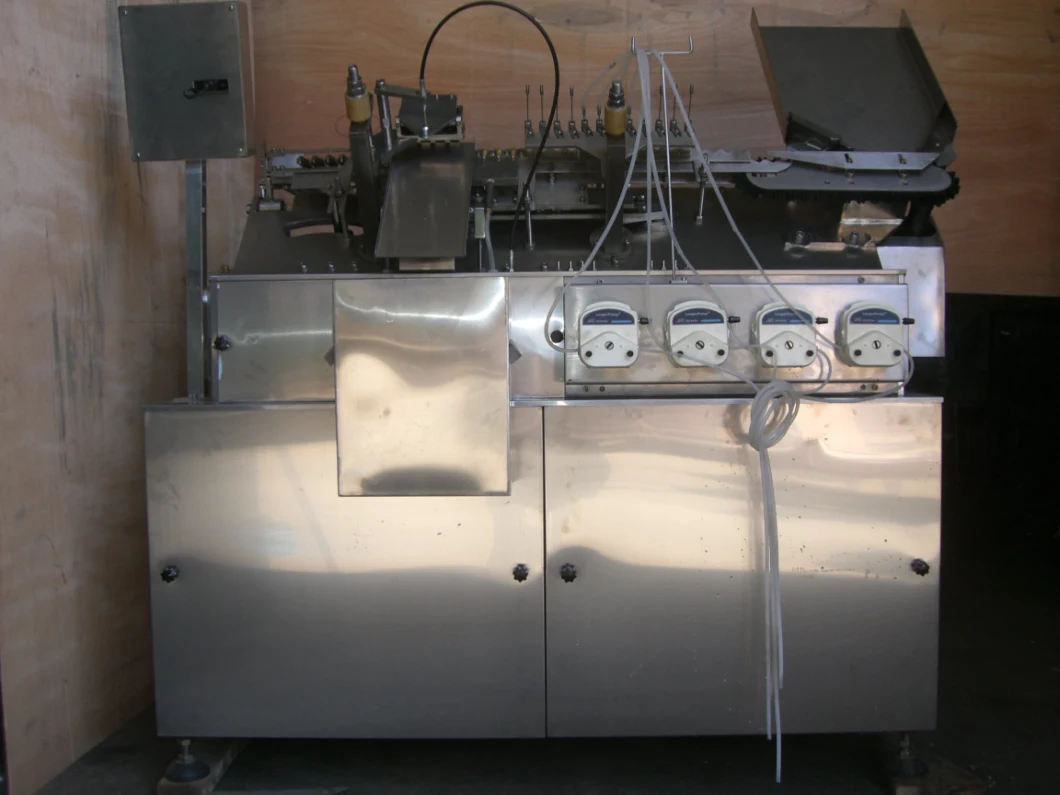

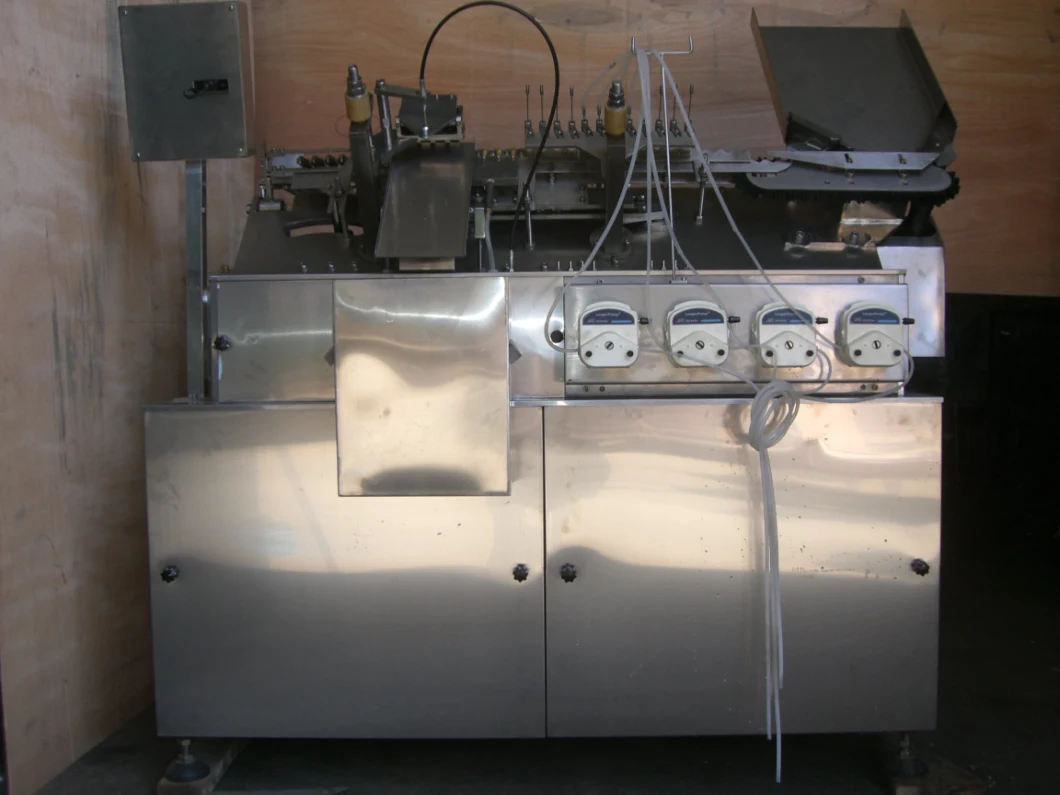

This product is a new type filling and sealing machine which had been recently researched,manufactured and developed by our company. It now becomes an upgrade product to replace ordinary ampule filling and sealing machine. Besides of some characters of the ordinary ampule wire-drawing filling and sealing machine, e.g. adopting the chain and rectangular methods to transfer ampule, these methods will be able to stop transferring ampule under the condition of non-stop machine; and adopting the mechanical stop-filling instrument when lacking of ampule bottle, this new machine has also added some new-type instruments of rotation speed adjustment and digital display, therefore the machine can easily control and find out the rotation speed of whole machine according to the product performance.

In addition, this machine has been set many filling heads in filling working positions, besides filling liquid, it can also simultaneously meet requirements of filling compressed air and filling nitrogen both front and back; Ampule-bottles moving in-out will be smooth and steady when whole machine in operation, the product pass-percent of this machine is quite high, therefore these machines have been extensively used in filling and sealing of pharmaceutics, health food production, cosmetics industry and some standard materials in scientific research departments.

Characteristics:

1.The ampoule bottle's feeding can be stopped while the machine is not stopped.

2.The filling can be stopped mechanically when lack of ampoule bottle.

3.There is the adjusting and displaying function for the rotating speed.

4.There are many filling heads in the filling stations.

5.Besides liquid, compressed air or nitrogen can be simultaneously filled from the front and the back.

6.Ampoule bottles' moving in/out is smooth and steady during the production.

In addition, this machine has been set many filling heads in filling working positions, besides filling liquid, it can also simultaneously meet requirements of filling compressed air and filling nitrogen both front and back; Ampule-bottles moving in-out will be smooth and steady when whole machine in operation, the product pass-percent of this machine is quite high, therefore these machines have been extensively used in filling and sealing of pharmaceutics, health food production, cosmetics industry and some standard materials in scientific research departments.

Characteristics:

1.The ampoule bottle's feeding can be stopped while the machine is not stopped.

2.The filling can be stopped mechanically when lack of ampoule bottle.

3.There is the adjusting and displaying function for the rotating speed.

4.There are many filling heads in the filling stations.

5.Besides liquid, compressed air or nitrogen can be simultaneously filled from the front and the back.

6.Ampoule bottles' moving in/out is smooth and steady during the production.

| Technical Parameters | |||||||

| Model | UBD2 | UBD4-A | UBD4-B | UBD6-A | UBD6-B | UBD8 | |

| Filling Needles | 2 | 4 | 4 | 6 | 6 | 8 | |

| Specification (ml) | (1-2) OR (5-10) | (1-2) OR (5-10) | 5-20 | (1-2) OR (5-10) | 5-20 | (1-2) OR (5-10) | |

| Output (Pieces/min) | 45-60 | 90-130 | 60-100 | 135-200 | 90-150 | 180-260 | |

| Power (Kw) | 0.37 | 0.55 | |||||

| Energy consumption | Gas(m³/h) | 2-2.5 | 2-2.5 | 3-3.5 | 4-4.5 | ||

| LPG (kg/h) | 1 | 1 | 1.5 | 2 | |||

| Consumption of oxygen (Kg/h) | 7 | 7 | 10 | 12 | |||

| External dimensions (mm) | 1100x720x1500 | 1540x980x1500 | 1980x1000x1500 | 2400x1000x1500 | |||

| Weight (Kg) | 250 | 330 | 350 | 470 | 500 | 680 | |

| Power supply | 220V50Hz | ||||||