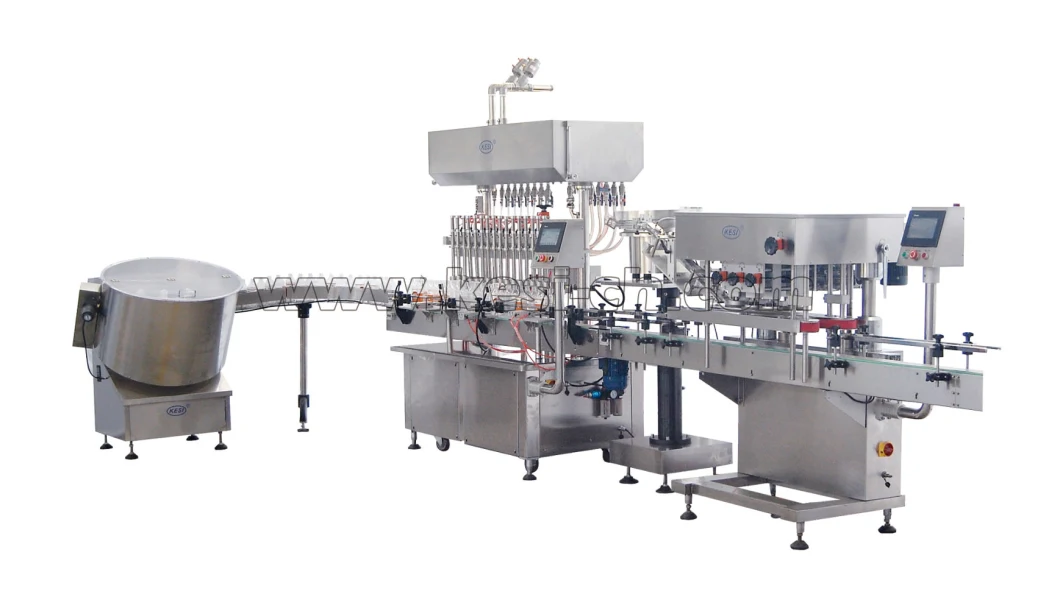

Medicine, Pharmaceutical, Chemical, Cosmetic Filling Machine (YBG)

The timed flow volumetric filling machines are controlled by the piston to ensure filling precisely. The product bulk supply is pumped into a holding tank above a set of pneumatically operated valves. Each valve is independently timed by the filler's master computer so that precise amounts of liquid will flow by gravity into the container.

Characteristic

1. Within a single filling cycle can satisfy the large load requirement through several times filling.

2. The interface and PLC control system is easy-to-use.

3. A pneumatic valve to protect bottles from nozzle dripping,

4. Servo nozzle height/dive option available

5. No Product/No Fill (suspend operation)

6. No Bottle/No Fill (suspend operation)

7. Downstream Back-up/No Fill (suspend operation)

Technical Parameters

Application

This machine can be applied to all various stand-free containers, and is widely used in all industries, such as cosmetic, light industry, pharmaceutical, chemical, agrochemical, and food& beverage etc..

Our Partnership

Shanghai Kesi Packaging Machinery Co., Ltd is the only service provider of German LANGGUTH GmBH in China.

Our Certification

About KESI

Established on 1998, Shanghai Kesi Packaging Machinery Co., Ltd has been committed to machinery industry for more than 18 years. Our products include and not limited to:

1. Unscrambler for various packing lines

2. Filling Machine

3. Capping Machine

4. Sealing Machine

5. Labelling Machine

For further information, please visit our company website kesibaozhuang.en.made-in-china.com.

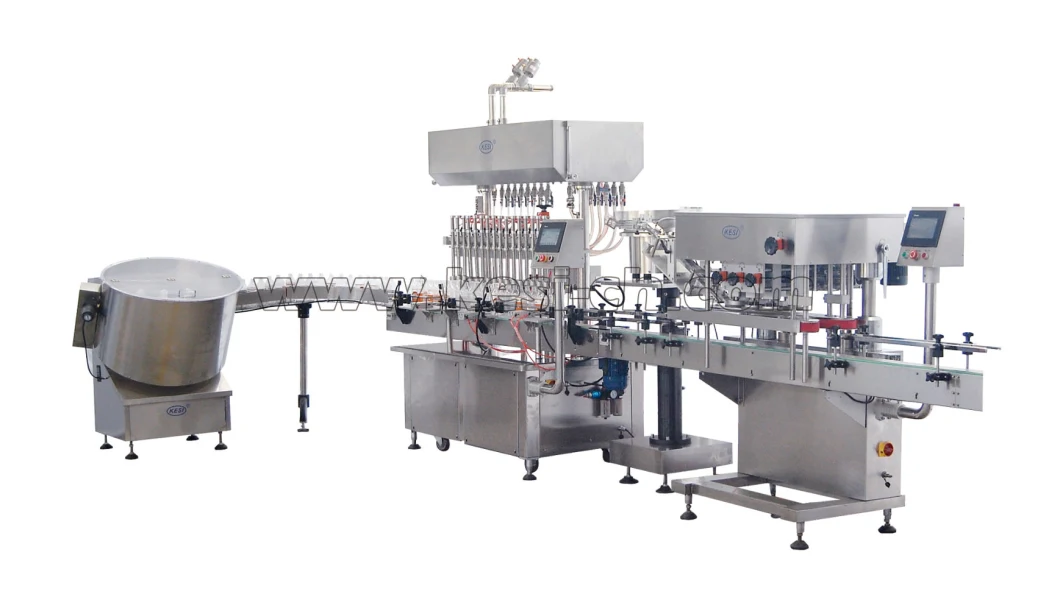

The timed flow volumetric filling machines are controlled by the piston to ensure filling precisely. The product bulk supply is pumped into a holding tank above a set of pneumatically operated valves. Each valve is independently timed by the filler's master computer so that precise amounts of liquid will flow by gravity into the container.

Characteristic

1. Within a single filling cycle can satisfy the large load requirement through several times filling.

2. The interface and PLC control system is easy-to-use.

3. A pneumatic valve to protect bottles from nozzle dripping,

4. Servo nozzle height/dive option available

5. No Product/No Fill (suspend operation)

6. No Bottle/No Fill (suspend operation)

7. Downstream Back-up/No Fill (suspend operation)

Technical Parameters

| Speed (8 nozzles) | 30----80bottles/min |

| Container Size | 50ml----1000ml |

| Accuracy | ≤ ± 0.5% |

| Power Supply | 220, 50(V , Hz) |

| Power | 1kw |

| Air Pressure | 0.4MPa----0.6MPa |

| Air consumption | 0.5m3 |

| Weight | 550kg |

| Dimension | 2100mm*1640mm*1670mm |

| Special needs upon your request | |

Application

This machine can be applied to all various stand-free containers, and is widely used in all industries, such as cosmetic, light industry, pharmaceutical, chemical, agrochemical, and food& beverage etc..

Our Partnership

Shanghai Kesi Packaging Machinery Co., Ltd is the only service provider of German LANGGUTH GmBH in China.

Our Certification

About KESI

Established on 1998, Shanghai Kesi Packaging Machinery Co., Ltd has been committed to machinery industry for more than 18 years. Our products include and not limited to:

1. Unscrambler for various packing lines

2. Filling Machine

3. Capping Machine

4. Sealing Machine

5. Labelling Machine

For further information, please visit our company website kesibaozhuang.en.made-in-china.com.